China Brake Pads Factory-Ketullabrakes

China Brake Pads Factory-Ketullabrakes

Blog Article

Introduction to China Brake Pads factory

As a leading China brake pads factory, Ketulla understands the vital role that quality plays in the automotive industry. The brake pads industry in China is expansive and competitive, and this blog will explore the types of brake pads produced, the manufacturing process, and key considerations for sourcing brake pads.

The Landscape of Brake Pads Factories in China

With the rapid development of the automobile industry, China as the world factory, auto parts are also growing, with brake pads as an important part of the auto parts, more than 1,000 enterprises of this scale have emerged.

China boasts a multitude of brake pads factories, particularly in regions like Shandong, Jiangsu, and Zhejiang. Ketulla is proud to be part of this dynamic industry, producing high-quality brake pads for both domestic and international markets.

Types of Brake Pads Manufactured in China

At Ketulla, we manufacture several types of brake pads, including:

- Ceramic Brake Pads: Renowned for their quiet operation and reduced rotor wear.

- Semi-Metallic Brake Pads: Designed for high-performance applications, ideal for trucks and buses.

- Low-Metallic Brake Pads: Offering a balance between noise and performance.

This section details each type and highlights Ketulla’s commitment to quality. - Truck/Bus brake pads: Ketulla developed A brake pads materials formula, Mainly for truck and bus brake pads on the market, it can provide high performance with heat-resistant and environmentally friendly brake pads to ensure our driving safety

Brake Pads Manufacturing Process in China

Discover the step-by-step process involved in manufacturing brake pads at Ketulla’s factory.

check our blog how to produce brake pads

The production of Ketulla brake pads involves:

- Material Selection: Sourcing high-quality raw materials.

- Mixing: Combining ingredients for optimal performance.

- Pressing: Molding the mixture into the desired shape.

- Curing: Enhancing durability through curing processes.

- Quality Control: Implementing rigorous testing to ensure reliability.

This process guarantees that our brake pads meet the highest standards.

Current Condition of Brake Pads in China

Understand the current state of brake pads in China, including quality standards and market trends.

Content:

The condition of brake pads in China is evolving rapidly, with a growing emphasis on quality and performance. Many manufacturers, including Ketulla, adhere to international standards such as ECE R90 and IATF 16949.

Recent trends show an increasing demand for high-performance and eco-friendly brake pads, reflecting global shifts toward sustainability. Additionally, consumers are becoming more discerning, seeking products that not only meet safety regulations but also offer improved longevity and performance.

How Long Do Factory Brake Pads Last?

How long do factory brake pads last? Learn about factors influencing brake pad lifespan from Ketulla.

Content:

Factory brake pads, including those from Ketulla, typically last between 30,000 to 50,000 miles, depending on driving conditions and maintenance. Factors such as vehicle type and usage significantly impact their longevity.

Factory Brake Pads vs. Aftermarket Brake Pads

Compare Ketulla’s factory brake pads with aftermarket options to determine the best fit for your vehicle.

Content:

When considering brake pads, it’s essential to evaluate factory options versus aftermarket.

- Factory Brake Pads: Engineered for specific vehicles, ensuring optimal performance.

- Aftermarket Brake Pads: Offer diversity but can vary in quality.

This comparison will assist customer in making informed decisions tailored to their needs.

Specifications of Factory Brake Pads

What kind of brake pads come from the factory? Understand the specifications and quality standards of Ketulla brake pads.

Ketulla’s factory brake pads adhere to strict specifications to meet safety and performance standards. This section details what to look for, including material quality and performance ratings.

Specifications:

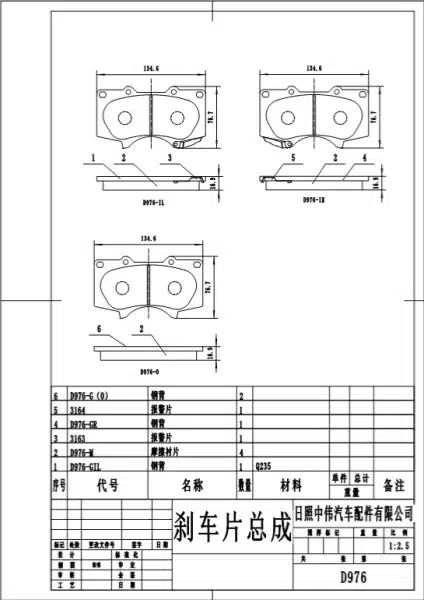

In strict accordance with international standards, and the size of each brake pad is marked, customers can be verified by the size of the brake pad we provide, which is mainly determined by the size of the steel back of the brake pad, and the thickness of the friction material is also ground in accordance with the thickness of the drawing, to ensure that the brake pad can be successfully installed to the car.

China Factory Prices for Brake Pads

Prices for Ketulla brake pads vary based on type, quality, and order volume.

Understanding these factors will help buyers negotiate competitive deals without compromising on quality.

According to the price of our ketullabrakes company, first of all, we are a production factory, we provide wholesale prices for buyers, mainly to ensure that customers must have a reasonable profit margin, as follows:

Semi-metal brake pads are 5% higher than the price of low metal brake pads, and ceramic square brake pads because the cost of materials is higher than the material of low metal brake pads, so low metal materials are 30% higher;

Why Source Brake Pads from China?

There are many advantages to purchasing brake pads from China, first of all, the current management costs are lower than in some developed countries, and the finished products are of many kinds and can basically cover most of the models in the world, in line with international quality standards.

Ketullabrake is a leading professional brake pad production factory in China. The company has 24 years of manufacturing and sales experience since its establishment in 2000. It has 2,351 different brake pads, which can cover 98% of the global models, and is also the chairman of the China Friction Materials Association.

Final Thoughts on Choosing Brake Pads from China

In conclusion, the brake pads manufacturing industry in China is robust, with Ketulla leading the way in quality and performance. By understanding the types, manufacturing processes, and pricing, buyers can make informed decisions when sourcing brake pads.